K-MAC Nissan 280 ZX (1978- 1983)

Front Strut Plates Camber & Caster kit

(Stage 3- Full Race). # 541116- 3L

FRONT- Camber (AND ALSO CASTER)

FRONT- Camber (AND ALSO CASTER) REAR- Camber ( AND ALSO TOE )

REAR- Camber ( AND ALSO TOE )

FRONT- Camber

FRONT- Camber (AND ALSO CASTER)

REAR- Camber

REAR- Camber (AND ALSO TOE)

ALLOWS TO ADJUST TIRE CONTACT ANGLES. ESSENTIAL FOR MORE EVEN TIRE WEAR TRACTION, ALSO ADJUSTING FOR UNDERSTEER OR OVERSTEER.

KMAC unique design – Single wrench, precisely adjustable. Accurately under load, direct on alignment rack.

Allowing to adjust, increase Positive Caster to reduce dive, lift under brake and acceleration. Improve high speed directional control, Better turn in, Correctly resolve steering pull.

But the very highest 7075 aircraft grade aluminum with “Extra H/ Duty” self align spherical bearings – massive 30 mm ID by far biggest in the industry (self lubed – PTFE lined). KMAC Stage 3 unlike Stage 2, there is no elastomer / flex allowing for tauter / quicker response times! – More effective shock control. Specifically for full race applications where ride harshness and durability are not the criteria.

ANOTHER KMAC UPDATE INCORPORATED INTO THE DESIGN: Separate radial thrust bearings to take the “Steering Loads” (which also resolves annoying spring drag/ noise/ binding). Massive 85mm (3 3/8″) diameter fully sealed bearings (again by far biggest in the industry) and also included are OEM diameter alloy top spring seats (along with separate seats to suit all brands of coil overs 60-70mm I.D.).

FEATURES / ADJUSTMENT RANGE: Replaces the existing Strut Top Mounts (no modifications). Reinforcing the strut towers and with the unique KMAC patented design providing the biggest (and quickest) adjustment range of both Camber and Caster. Street/Race settings can be recorded and changed in 30 seconds – just the time taken to loosen the 3 top mount nuts. Another KMAC Patented design feature allows this fast adjustment to be made accurately (under load) direct on alignment rack.

NOTE : SUPERSEDES THE CURRENT INDUSTRY STANDARD WHICH HAS BEEN AROUND FOR YEARS – ‘SLOT’ adjustment. Unlike KMAC are only available in a solid / uncompromising STAGE 3 Full Race version (steel sphercial bearings mounted on a non shock absorbing steel plate).

THIS SLOT DESIGN, BESIDES PROVIDING LESS ADJUSTMENT because of the need for access to the hold down bolts, is also time-consuming to adjust and on many vehicles requires removal of the strut.

Note : Most brands the “single” spherical ball is also taking the steering loads.

Unlike KMAC where all Stage 2 (Street/ Race) and Stage 3 (Full Race) incorporate purposely designed vertical thrust bearings ( these are fully sealed and massive 85 mm diameter). Reducing steering effort and preventing annoying noise through spring drag / binding.

ON TRACK DAYS : ABILITY TO DIAL IN “EXTRA NEGATIVE CAMBER” TO SIGNIFICANTLY REDUCE UNDERSTEER, in the pursuit of hitting these corner apexes every time and allowing to go deeper into the corners with increased traction and braking response. With the result of further lowering lap times in the quest for front row of the grid on race days ! (also see below front lower control arm adjusters for extra adjustment.)

RESULT : Finally – The adjustment capability TO CHANGE TIRE “CONTACT ANGLES” to correctly resolve costly premature edge tire wear and steering pull. The result of other than showroom height conditions – day to day commuting, encountering high cambered roads, altered height through load carrying or lowering, fitting wide profile tires/wheels and curb knock damage. Along with the ability to improve traction understeer/oversteer.

*ALSO ● ● ● ● SEE COMPLETE RANGE OF “FRONT AND REAR BUSHINGS ” 1st. ITEM TO FAIL. ALL THE VERY LATEST DESIGN BREAKTHROUGHS (Experience of manufacturing performance bushings longer than anyone else – 1964). Resolving costly, premature bush wear with resultant wheel tramp, vibration, loss of traction under brake and acceleration.

CHECK LIST / EXTRA FEATURES KMAC BUSHES VERSES OTHER BRANDS: Where other brands merely replace “OEM rubber bushes with urethane “ to eliminate the OEM oil and air voids in the endeavour to improve brake and steering response. The problem here is that with today’s autos multi link arms and different mount angles, this inhibits the suspension arms traveling through their required arcs which can cause even more wheel tramp / loss of traction with arms binding, locking up and lead to breakage!

KMAC bushings therefore where required are “Mono ball / 2 axis / self aligning ” with the unique design providing more than two and a half times for both the load bearing area and shock absorption over of OEM bushes.

This KMAC design breakthrough also finally resolving once and for all the issue with “steel spherical bearings“. Their wafer thin teflon style liners used soon pounding out with resultant metal to metal contact, noise.

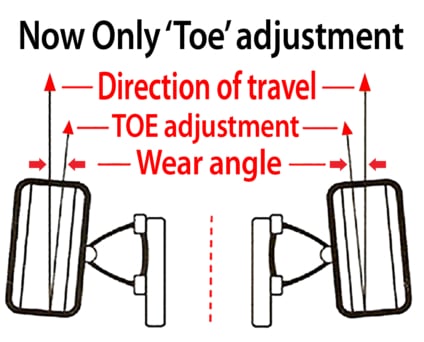

Also because of ever increasing speed of assembly lines virtually all today’s Autos now only have Front and Rear Toe “directional adjustment”. Most KMAC bushings therefore are adjustable for Camber and Caster allowing to change tire “contact angles” – essential to resolve costly premature edge tire wear and correctly fix steering pull.

THE ACTUAL KMAC “PATENTED DESIGN BUSH ADJUSTMENT SYSTEM” HAS REVOLUTIONIZED THE INDUSTRY – PRIOR TO THIS – THE LAST 40 OR SO YEARS HAS REQUIRED THE NEED FOR LABOUR INTENSIVE DISASSEMBLY AND BUSH REMOVAL. THEN THE INACCURATE TRIAL AND ERROR NEED FOR BUSH REPOSITIONING EACH TIME TO CHANGE ALIGNMENT SETTINGS. INSTEAD NOW WITH KMAC WE HAVE CHANGED ALL THAT – IT IS PRECISE SINGLE WRENCH ADJUSTMENT ACCURATELY ON CAR (UNDER LOAD) DIRECT ON ALIGNMENT RACK. THEN SECURED BY THE K-MAC UNIQUE “POSITIVE LOCK” SYSTEM.